Radar Innovations Laboratory

A 35,000 square foot laboratory dedicated to innovations in radar technology and science.

The Radar Innovations Laboratory, or RIL, is a 35,000 square foot state-of-the-art facility dedicated to advancing OU's radar program. The laboratory includes a large microwave lab with seating for 70 students, 22 staff, and 18 faculty members, a high-bay garage for mobile radar platforms, prototype fabrication facilities, a fully stocked machine shop, two precision anechoic chambers, an experimental observation deck, state-of-the-art classroom and seminar space, and a unique "Ideas Room" for fostering collaboration and innovation. Located just east of the National Weather Center, the RIL has been open since 2015 and has become an integral part of the OU South Research Campus.

Facilities

Lobby and Tornado Simulator

Microwave Laboratory

High Bay

Fabrication Facilities

Machine Shop

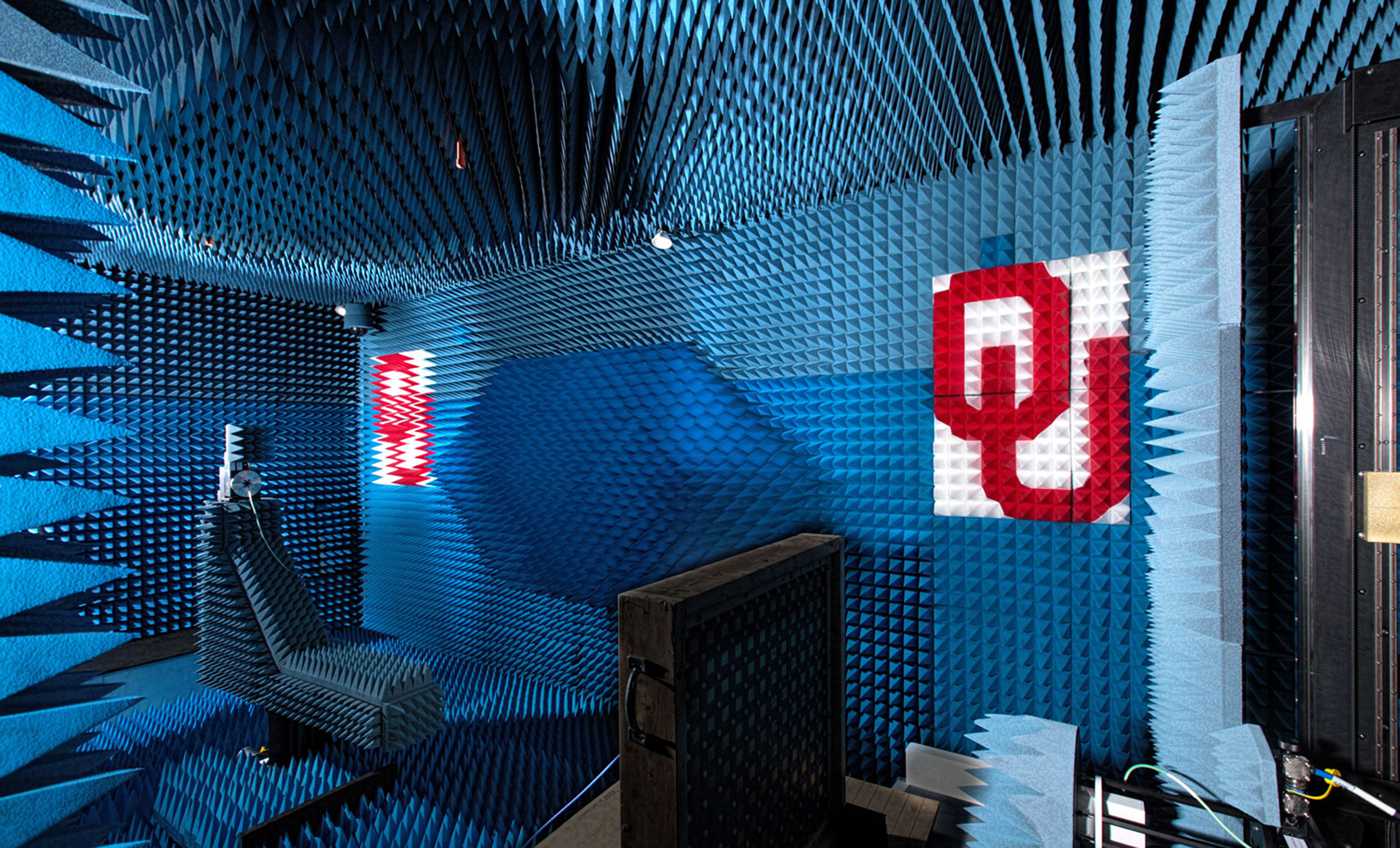

Anechoic Chambers

Experimental Observation Deck

State-of-the-Art Classroom and Seminar Space

Ideas Room

Instruments

The RIL has equipment to support research, prototyping and testing of radar and RF devices through 50 GHz.Major Test Equipment:

- VNA Copper Mountain Planar 804/1 with RF front extender CobaltFx FEV-10 Frequency Extension System, 75 to 110 GHz

- Agilent PNA and PNA-X Network Analyzers (up to 50 GHz for two ports, 26.5 GHz for 16-port analysis) with an electronic calibration module

- Agilent PSA and EXA Spectrum Analyzers with Phase Noise and Noise Figure Personalities (up to 50 GHz)

- Tektronix Real-Time Spectrum Analyzer with 110 MHz of instantaneous bandwidth (up to 14 GHz)

- Agilent PSG Analog Signal Generator (up to 50 GHz)

- Agilent PSG Vector Signal Generator (up to 31.8 GHz)

- Agilent Peak Power Meter (50 GHz)

- Agilent Oscilloscope (8 GHz)

- Anritsu Portable Spectrum Analyzer (13 GHz)

- Agilent Arbitrary Waveform Generator (125 MHz)

- Agilent Multi-channel data logger

- LPKF ProtoLaser U4 Micro-material processing

- Electroless- and electro-plating setup

- Multilayer lamination capabilities

- Extensive soldering and rework equipment

- Polymer chemical vapor deposition

- 3D solid free-form fabrication

- Photolithography patterning